Compact and Powerful

The 1924 sandcarving system is the perfect fit for any entry level to moderate production etching business. The compact size is ideal when space is limited. The cost effective price is perfect to add sandcarving to your current or new business. Start decorating glass, crystal, metal, wood, granite, stone and more with this powerful and versatile system, even in the smallest of spaces!

The 1924 sandcarving system has one side door entering a spacious cabinet lit with LED lighting. The system includes a stand-alone powerful 135 CFM dust collector that connects with a flexible 4’ hose to the back of the sandcarving system. The dust collector efficiently separates and traps dust and worn abrasive. The ACME certified 50lb pressure pot is built underneath the cabinet allowing abrasive to automatically recycle. This self-contained system is easy to use and has a large window providing a clear view of your etching.

Rayzist Sandcarving System Loaded with Standard Features!

FAQs

What is the main difference between the 2034VXA and 1924 Sandcarving System?

The two main differences between the 2034VXA and 1924 is the size of the blasting cabinet and dust filtration. The 2034VXA has a larger blasting cabinet with dual doors. The 1924 has a single door entrance to the slightly smaller blasting cabinet. The dust filtration is the main difference between the two systems. The 2034VXA has a built on HEPA filtration and this sandcarving system has the capability to operate for several hours. The 1924 has a stand-alone dust collector that is designed to operate for 60 minutes nonstop.

What types of materials will the 1924 sandcarve?

The 1924 system can sandcarve on glass, crystal, wood, natural stone and virtually any hard surface.

Is the dust filtration system included with the 1924 system?

A stand-alone dust filtration system is included with the purchase of a 1924 system.

What is the largest item I can sandcarve in the 1924 sandcarving system?

The inside working area measures at 24″w x 19″D x 24″H.

Can the 1924 sandcarving system be used for a production type set up?

The 1924 system is designed to handle the hobbyist and blasting type of set up, 60 minutes at one time. For mid to high production runs see the 2034VXA system.

Features

Pressure Pot

This 50 lb., ASME-certified pressure vessel houses the abrasive. It automatically filters out debris to prevent clogging. Our exclusive 45-degree angle design allows for a more consistent sand flow.

Stand-Alone Dust Collector

The stand-alone dust collector is a powerful 135 CFM unit that efficiently separates and traps dust and worn abrasive.

Ergonomic Cabinet Design

The cabinet design follows the contours of your natural position while sandcarving, which allows you to work comfortably and more productively.

Seam-Welded/Powder-Coated

The system is built to last for years, with total seam-welded, 14-gauge steel construction and an epoxy powder-coated finish. The epoxy powder-coated finish resists rust as well as chips, scratches and wears better than other types of finishes.

Gloveless Sleeves

The large gloveless sleeves are made of a lightweight polyurethane, for easy mobility and handling of your products while sandcarving.

Padded Arm Rests

The padded arm rests prevent stress to your forearms and provide added comfort while sandcarving.

LED Lighting

The single recessed LED lighting provides the brightest lit sandcarving workspace on the market. The LED light also ensures longer life and clean white light during operation.

Oversized Viewing Window

The oversized laminated safety glass provides superior visibility while sandcarving. The oversized viewing window can easily be replaced.

Exclusive Air Curtain

The Exclusive “Max Flow” Air Curtain directs air across your viewing window to remove dust and ensure maximum visibility while sandcarving. This process is made possible by a vent above the viewing window. It also, helps prevent dust and overspray to your viewing window.

Full Size Single Door Entry

The full-size single door entry is generous in size and opens on the right side of the cabinet. A large entry area minimizes the potential for bumping or nicking your sandcarved products.

Wheels

Locking wheels give you the flexibility to move your system when required.

Foot Switch Valve

This footswitch valve provides longer performance and is very low maintenance in comparison to the former footswitch valve. It also optimizes air and sand flow to your hoses.

Heavy Duty Blasting Hose

The 10 ft. heavy duty hose is flexible and provides adequate sand flow and longer blasting usage.

Carbide Nozzle

The durable 3/32-inch carbide nozzle is versatile and easy to use for any sandcarving project. It comes with an adapter and O-ring.

Pressure Regulator/Water Separator

This unit regulates the amount of air pressure and sand flow (PSI) being sent to your blasting hose/nozzle and efficiently separates the water content. We have combined the two functions into one unit to minimize space. Standard features include an auto-relieving moisture drain to remove water drops and oil from compressed air, a push-down locking adjustment knob to change pressure settings, pressure gauge, liquid level indicator and manual relieving valve.

Epoxy Powder Coated

Pressure Pot Vessel is two-tone epoxy powder coated for durable and resistant finish

Powder Coating is a process called “Electrostatic Spray Deposition” (ESD) and is used to achieve the application of the epoxy powder coating to a metal substrate. An epoxy resin is cross-linked with a co-reactant or hardener, which when properly catalyzed and applied, the epoxies produce a hard, chemical and solvent resistant finish. This application method uses a spray gun, which applies an electrostatic charge to the powder particles, which are then attracted to the grounded part.

Powder coating results in a thick, dense finish on metal products which are more durable and last longer than conventional or industrial painting. Rayzist Photomask spends the extra effort and costs to ensure every sandcarving and automatic washout system is epoxy powder coated to produce the most durable finish.

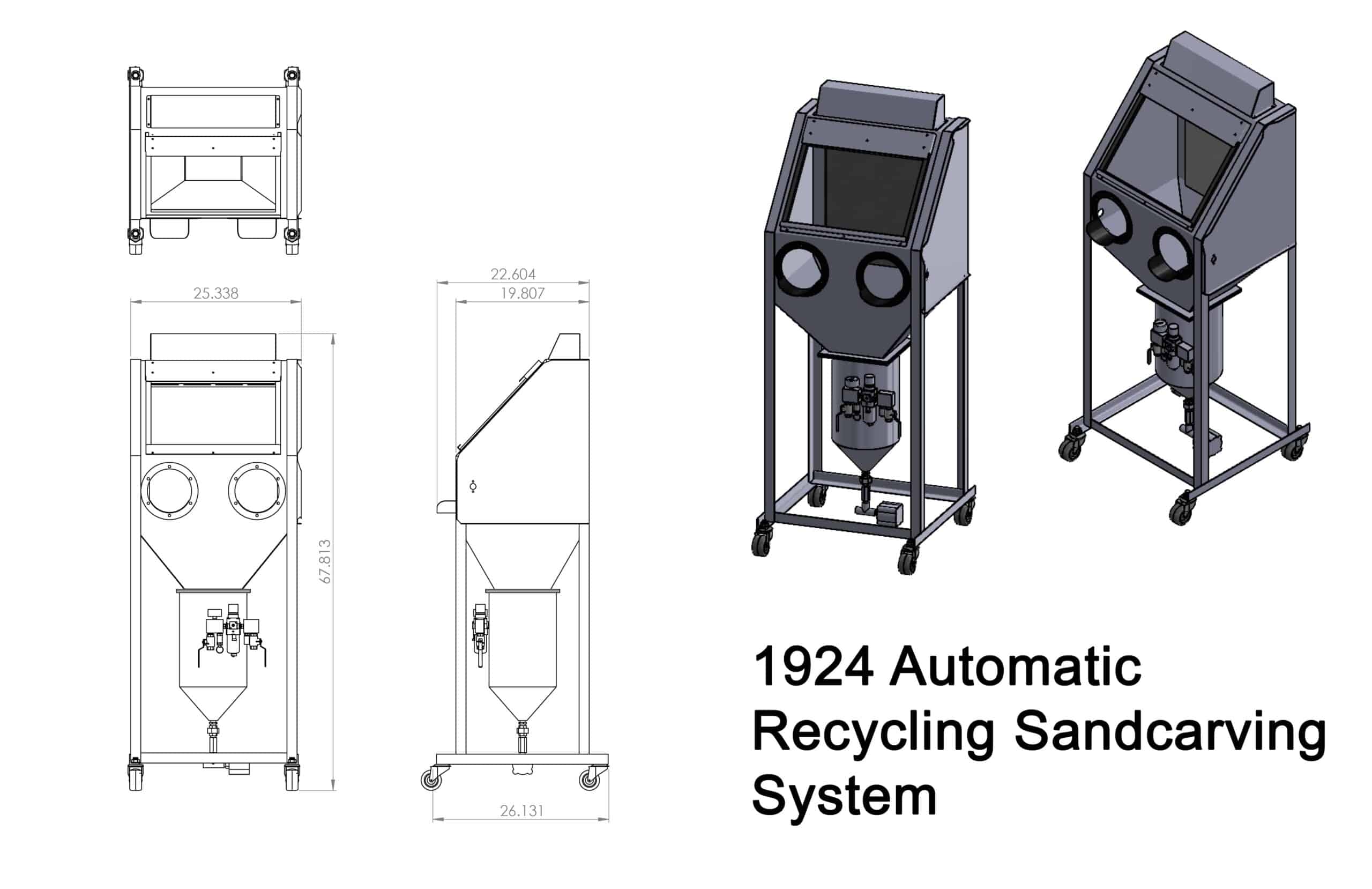

Technical Details

1924 Cabinet Specs:

Inside Work Space: 19″d x 24″w x 24″h

Outside Dimensions: 23″d x 25.5″w x 66″h

Shipping Weight: 400lbs.

The standard unit is 110 volt, 15 amp (220v 50h Power Conversion Upgrade Available)

Compressed Air Requirements: 5.5 CFM (or greater) at 90 psi to facilitate blasting pressures of 30 psi using 3/32″ nozzle.

Warranty

- Lifetime warranty on cabinet construction

- 1-year warranty on the motor

- 90-day warranty on water separator/regulator

- 90-day warranty on foot pedal, foot switch valve and heavy-duty blasting hose

Support

How often does the 1924 Dust Filtration System need to be maintained?

If the sandcarving system is operating daily or 5 hours per week it is recommended to clean the Filtration System once a week.

How is the Dust Filtration System clean?

The Dust Filtration System includes a filter cartridge that captures dust and debris therefore needs to be cleaned by removing the filter and using compressed air to free the filter of debris. There is also a breathable cloth bag that fits around the container, remove the cloth bag and empty any dust and debris located at bottom of container. Shake bag and replace. These two items will also need to be replaced over time.

Why does the abrasive and air continue to flow when the foot pedal is disengaged?

A – Confirm the air compressor output pressure is set to a minimum of 90PSI to Sandcarving System.

B – If the air compressor output pressure is set correctly, next confirm the tube sleeve inside Foot Switch Valve has not worn through creating a pinhole.

Why has air and abrasive stopped flowing out of the nozzle when the foot pedal is engaged?

The most common issue is a clog. A clog can consist of a small piece of sandcarving film or debris. Follow the steps below to unclog the blasting stream.

A. Remove nozzle and nozzle holder. Look through nozzle and confirm that there is no obstruction. If nozzle is clear, set aside and proceed to following steps.

B. Close sandflow valve.

C. Open air low valve 100%.

D. Set on pedal.

E. If no air flows through sandblast hose, open the sandflow valve and close the blasting air valve. Increase blasting pressure 5-10PSI and step on foot pedal.

F. Once clog is removed reset air and sand flow valves, replace nozzle.

Is it normal to have large burst of abrasive come out of my nozzle during sandcarving?

A burst of abrasive is normal when first stepping on the foot pedal. If there is a burst of abrasive during sandcarving then the sandflow valve is open more than the airflow valve and the sand flow valve needs to close slightly. Close sandflow valve about a 1/4″ and step on the foot pedal for 20-30 seconds.

Why does it seem have more air than sand/abrasive coming out of the nozzle?

If it appears the air is taking over the sandflow stream then close the airflow valve slightly about a 1/4″. Step on the pedal for 20-30 seconds and repeat if air is still taking over sand blast stream. The sand and air valve should be at equal parts, 50%.

Why is epoxy powder coating better than an industrial paint application?

Epoxy powder coating is the highest form of treatment for metal surfaces. The is an expensive treatment to cover and protect the metal surface. Rayzist uses a two-tone wrinkle finish on all the sandcarving systems to guard against scratching and rust. In addition to powder coating the outside of the system, Rayzist also finish the inside of the blasting cabinet. The powder coated finish will protect the body of the sandcarving system longer than any industrial paint.

Shipping

The 1924 Sandcarving System shipping on a pallet with a double wall box by a trucking company. A lift gate is required upon delivery if a forklift or loading dock is not available.

Shipping weight: 400lbs

Note: Shipments may take 1-3 business days to process unless otherwise specified.

Ed R –

After years of hand engraving & watching youtube videos of sand carving.I finally said it is time to try and came across Rayzist 1924.I really have to say Rayzist makes it very easy to do sand carving and i am already producing items for sale 90 percent less time.The hardest thing i have to do now is pick the artwork.Rayzist does make it that easy I am very happy and looking to do business with them for a long time.Thanks again Anthony and the Rayzist family.

David and Christy –

We were in the market to add something to our small home based business that would put us over the top and would allow me to consider stepping down to part time at my 40 hour a week job. After quite a bit of investigation and countless hours spent researching Sandblasting and equipment manufacturers and such, we finally decided upon Rayzist. And it turned out to be the RIGHT decision. The customer service was excellent. No pressure, no typical salesmanship, just simple straight forward information and follow thru. We purchased the 1924 System and masking kit. Excellent quality construction and totally user friendly. While waiting for the delivery we purchased an air compressor and did the break in. Upon arrival, we uncrated the well packed cabinet, assembled according to instructions and blasted our first piece of glass with in minutes of set up. WOW,,,it was that easy, that fast and the result was unbelievable. We come from a embroidery, sublimation, CNC, vinyl, heat trasfers, screen printing and photo editting back ground, which all of takes a fairly long learning curve. My wife did her first blasting design and I did my second within minutes of the first with outstanding results. No glass, no bottle, no brick, no wood, no stainless steel and no dog bowl is safe in my house as we learn how to sandblast. And we even experimented with using vinyl as a stencil material. Fantastic results there too. The Rayzist system and cabinet is TOP QUALITY hardware. We were very fortunate in having Art as our salesperson and consultant. He is a gentleman, professional and extremely knowledgeable. Having dealt with the industry in our other mediums, it has been a complete pleasure in dealing with Rayzist. I look forward to a long future with Rayzist. I rate Rayzist well beyond good, more like Extremely Excellent.

Ed Falstrem –

Since taking delivery of a new sandblasting cabinet from Rayzist – the model 1924 and am turning out products with confidence in the machine and the quality of the photo resist.

Stephen M. –

I LOVE MY MACHINE. It works as promised every single time and I was just looking for alternatives to sand-carve into tile (who knows why I want to do that but at age 61 I’ve learned to just go with it). I find internet clipart either too expensive (since I have to actually make it as well as pay for it) or not to my liking as far as subject matter. That’s why I was looking to Rayzist for additional subjects since the previous stencils I have purchased have all been first rate. I guess pre-made stencils are not all that lucrative since I really don’t see much of an expansion in the inventory but, still, I don’t do much in the way of generic kind of sand-carving. I wish there was more in the way of visually creative options, since what I learned about myself is I’m not really a conceiver I’m an implementer and what I need to do is see the picture and it just sort of jumps into my head and says "Hey, blast this into a tile. Maybe this would work with that – yada, yada, yada" and next thing you know I’ve got a masterpiece to hang on the wall. Anyhow, Rayzist customer service has proven, yet again, I made the right choice when I bought my machine. Thanks again.